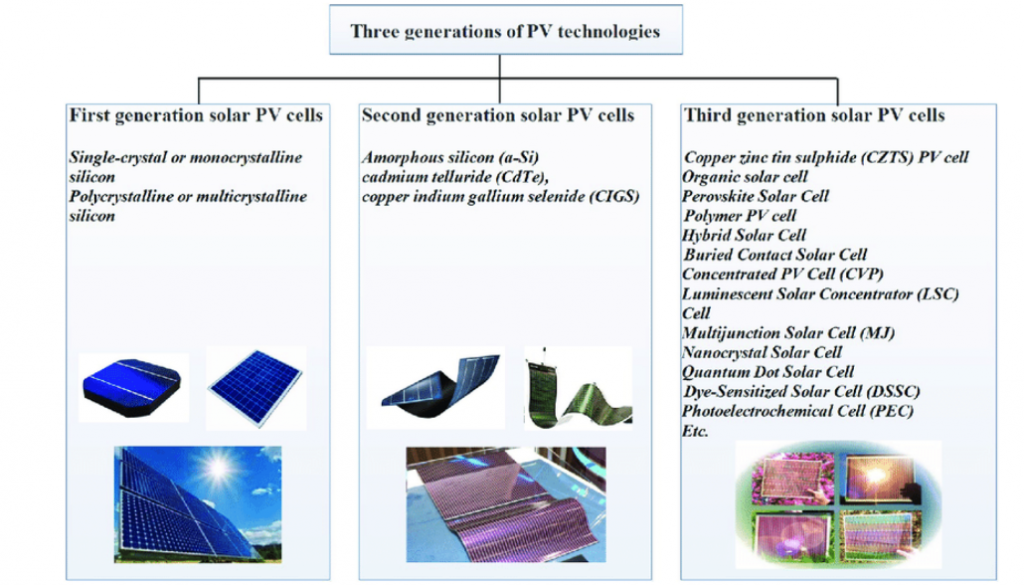

The purpose of this section is to explain different types of photovoltaic technology present today in the world and to provide the achievements in the field of advanced photovoltaic and photo chemical conversion of solar energy into electricity. Solar cells are produced up to recent years in three main categories. The first generation consists of relatively costly solar cells with low efficiency. The second generation contains solar cell types, which have even lower efficiencies but are considerably cheaper than those of the first-generation cells. The cost per watt is lower. Most technologies in this generation are not yet commercial, but there is a lot of research going on in this area. The goal is to make third generation solar cells cheap to produce.

The first generation of solar technologies employs inorganic molecules principally element as a medium of gather solar power, the second generation of solar cells used compound semiconductors like GaAs, CdTe, a-Si etc along with the introduction of thin film based mostly solar cells utilizing inorganic molecules. The third generation of solar cells use organic molecules principally semiconductor polymers as a solar absorbent for the fabrication of answer processed solar cells (Figure.1 ).

Third generation cell is largely involving the utilization of nanocrystalline (quantum dot) materials guarantees that potency on the far side the Schockly-Quessier limit. This class of solar cells includes: (i) organic solar cells (OSCs); (ii) dye supersensitive cells (DSCs); that area unit supported blends of semi conductive polymers and mixture semiconductor nanocrystals (NCs) (formed by 2 categories of materials characterised by wide optical absorbance of conjugated polymers and conductive , tuneable optical band gap and high material constant of nanocrystals).

Photovoltaic cells based on organic molecules have recently developed as a possible replacement for the traditional solar cell based on silicone. Over the inorganic, organic solar cells benefit from low cost, durability and low weight of the unit. The polymers are however volatility and low power transfer form due to exposure to oxygen and humidity. However, the polymers instability under exposure to oxygen and humidity as well as low power conversion efficiency, the main challenges for the realization in the energy market of organic thin film solar cells remain. Organic solar cells mainly comprise a photoactive medium consisting of a variety of p-type semiconductor polymers and nanostructuring compleerene molecules as electron acceptors. However, a number of other nano-composites are also playing a critical role in the charge transport process which lead to improved device performance and device stability.

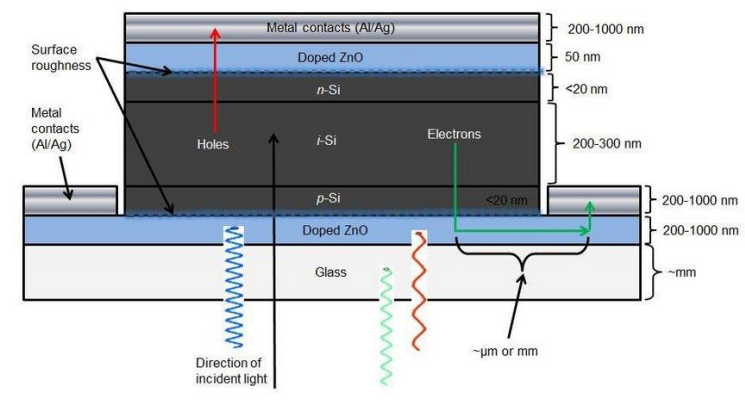

Amorphous Silicon Solar Cell (A-Si)

The non-crystalline form of silicone is amorphous silicon (a-Si). It has been on the market for more than 15 years now, the most well-developed thin film technology. It is used in pocket calculators but it also serves other private homes, houses and remote installations.

Thin film solar cells, ~1 um thick, have been fabricated from amorphous silicon from a glow discharge in silane. The cells were made in a p-i-n structure by using doping gases in the discharge. The best power conversion efficiency to date is 2.4% AM-1 sunlight. The maximum efficiency of thin-film amorphous silicon solar cells is estimated ~14-15%.

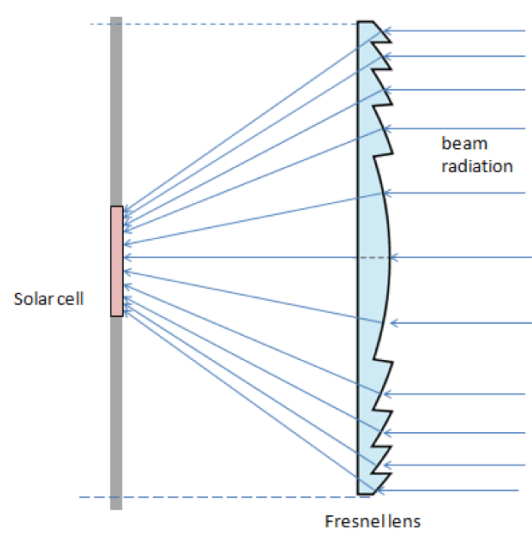

Concentrated PV Cell (CVP and HCVP)

With daylight, an innovative device transforms light-weight energy into current, within the same manner as ancient photovoltaic technology, however needs a large space of sunlight for optimum performance to focus on every cell. These multi-junction forms of solar panels have an potency rate up to forty first, which, among all photovoltaic systems, is the highest to date. In distinction with different solar battery types, the name of those CVP cells refers to the effectiveness: angular mirror plates, lenses and even cooling systems are used for bundling solar rays and so improving their efficiencies.

Specific CPV definitions exist, distinguished at times by the concentration component (LCPV) and high concentration (HCPV). Photovoltaic concentrator (CPV) is a solar generator. Unlike standard photo-voltaic systems, the lens is used to focus on small, but highly efficient, multi-junction (MJ) solar cells with curved mirrors. CPV systems commonly use solar trackers and a cooling system to further improve their performance. Continuing research and development in the infrastructure sector and in areas of high solar insulation is rapidly increasing their productivity.

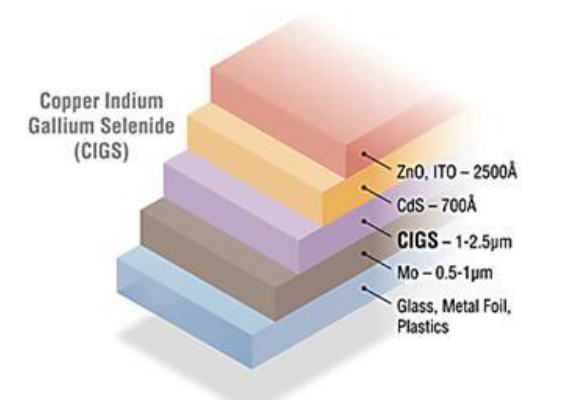

Copper Indium Gallium Selenide Solar Cells (CI (G) S)

One of the foremost interesting and polemical materials in solar is Copper-Indium-GalliumSelenide, or CIGS for brief. It had been a part of a solar thin-film-hype cycle wherever some CIGS corporations like Solyndra, NanoSolar and MiaSolé virtually became unit names. A copper metallic element gallium selenide electric cell (or CIGS cell, generally CI(G)S or CIS cell) may be a thin film solar cell wont to convert sunlight into electrical power. they’re manufactured by depositing a thin layer of copper, indium, gallium and selenide on glass or plastic backing, along with electrodes on the front and back to gather current. As a result of the fabric includes a high absorptance and powerfully absorbs sunlight, a far thinner film is needed than of different semiconductor materials.

Biohybrid Solar Cell

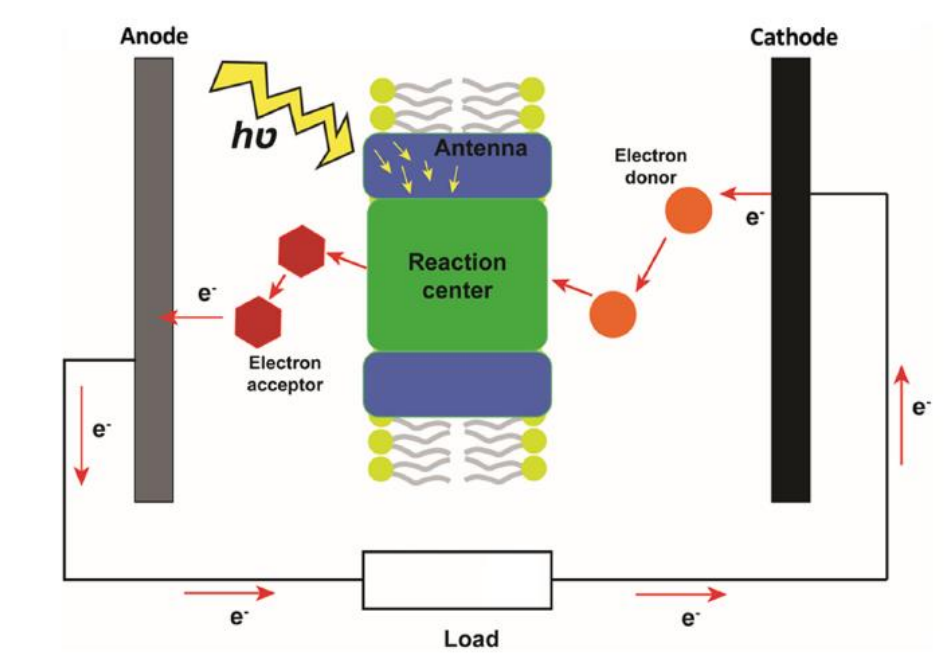

The Bio-hybrid solar cell is one of the types of solar panels that is still in the research phase. It has been discovered by an expert team at Vanderbilt University. The idea behind the new technology is to take advantage of the photosystem I (a photoactive protein complex located in the thylakoid membrane) to recreate the natural process of photosynthesis to obtain a greater efficiency in solar energy conversion.

Multiple layers of photosystem I gather photonic energy, convert it into chemical energy and create a current that goes through the cell. The cell itself consists of many of the same nonorganic materials that are found in other solar cells with the exception of the injected photosystem I complexes which are introduced and gathered for several days in the gold layer. After days the photosytem I are made visible and appear as a thin green film. It is this thin film that helps and improves the energy conversion. The bio hybrid cell however, is still in the research phase.

Cadmium Telluride Solar Cell (CdTe)

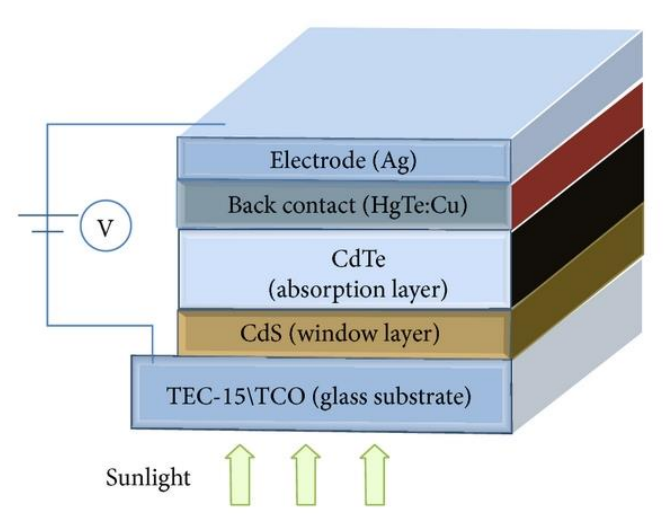

Cadmium Telluride Solar Cell (CdTe) Cadmium telluride (CdTe) photovoltaics describes a photovoltaic (PV) technology that is based on the use of cadmium telluride, a thin semiconductor layer designed to absorb and convert sunlight into electricity. Cadmium telluride PV is the only thin film technology with lower costs than conventional solar cells made of crystalline silicon in multi-kilowatt systems.

CdTe-based PV is considered a thin-film technology because the active layers are just a few microns thick, or about a tenth the diameter of a human hair. A schematic of a typical CdTe solar cell is shown here. Transparent conducting oxide (TCO) layers such as SnO2 or Cd2SnO4 are transparent to visible light and highly conductive to transport current efficiently. Intermediate layers such as CdS under low temperature conditions, the effective discharge capacity and effective discharge energy of lithium-ion batteries will be significantly reduced, help in both the growth and electrical properties between the TCO and CdTe. The CdTe film acts as the primary photo conversion layer and absorbs most visible light within the first micron of material. Together, the CdTe, intermediate, and TCO layers form an electric field that converts light absorbed in the CdTe layer into current and voltage. Metal is placed on the back to form electrical contacts.

The more amounts and quality of solar cells in a solar panel, the more total electrical output the solar panel will produce. It’s difficult to give an exact value of output because different types of solar panel will come out with distinct output and average percentage of efficiency.

Thin-film solar cells are becoming more popular, as they are much thinner, more durable, and cheaper than regular solar cells. Unfortunately, thin-film solar cells do have a downside: they have approximately a 10% efficiency rate, whereas regular solar cells have on average a 20% efficiency rate. Solar cells are typically named after the semiconducting material they are made of. These materials just have certain characteristics in order to absorb sunlight. Some cells are designed to handle sunlight that reaches the Earth’s surface, while others are optimized for use in space.